The Silent Guardian: Unpacking the Critical Role of Packaging in the Pharmaceutical Industry

1. Introduction: The Crucial Role of Packaging in the Pharmaceutical Industry

In the intricate and highly regulated world of pharmaceuticals, the importance of packaging often goes unnoticed by the end consumer. Yet, pharmaceutical packaging is far more than just a container for medication; it is a critical element in ensuring the safety, efficacy, and quality of pharmaceutical products throughout their lifecycle. From the moment a drug is manufactured to the time it is administered to a patient, the packaging plays a vital role in protecting it from environmental factors, providing essential information, and facilitating proper usage. This article will delve into the multifaceted functions, diverse types, stringent regulations, and emerging trends within the pharmaceutical packaging industry, highlighting its indispensable contribution to healthcare.

Toc

2. Primary Functions of Pharmaceutical Packaging:

Pharmaceutical packaging serves a multitude of essential functions, each contributing to the integrity and appropriate use of medications.

2.1. Protection

The primary function of pharmaceutical packaging is to protect the drug product from various external factors that could compromise its quality and safety. This includes protection from:

- Moisture: Excessive moisture can lead to degradation, chemical reactions, and microbial growth.

- Light: Exposure to light, particularly ultraviolet (UV) radiation, can cause photochemical degradation of certain drugs.

- Oxygen: Oxidation can alter the chemical composition and reduce the potency of medications.

- Temperature: Extreme temperatures, both hot and cold, can affect the stability and efficacy of pharmaceutical products.

- Physical Damage: Packaging must protect the drug from crushing, impact, and other physical stresses during transportation and handling.

- Microbial Contamination: Maintaining sterility is crucial for many pharmaceutical products, and packaging plays a vital role in preventing microbial ingress.

2.2. Preservation

Closely related to protection, preservation involves maintaining the drug product’s quality, potency, and shelf life. Proper packaging helps to prevent degradation and ensures that the medication remains effective until its expiration date. This is particularly important for sensitive drugs like biologics and vaccines.

2.3. Containment

Packaging provides a means of containing the pharmaceutical product, preventing leakage, spillage, or loss during handling, storage, and transportation. The container must be compatible with the drug product and not interact with it chemically.

2.4. Information

Pharmaceutical packaging is a crucial vehicle for conveying essential information to healthcare professionals and patients. This includes:

- Product Name and Strength: Clearly identifying the medication and its dosage.

- Manufacturer Information: Providing details about the company responsible for the product.

- Dosage Instructions: Guiding patients on how to use the medication correctly.

- Route of Administration: Specifying how the drug should be administered (e.g., oral, intravenous).

- Storage Conditions: Indicating the required temperature and other storage instructions.

- Expiration Date: Providing the date after which the medication should not be used.

- Lot Number: Enabling traceability of the product in case of recalls or quality issues.

- Warnings and Precautions: Highlighting potential side effects, contraindications, and interactions.

- Ingredients: Listing the active and inactive ingredients in the formulation.

2.5. Compliance

Packaging can be designed to enhance patient compliance with medication regimens. Features like blister packs with day-of-the-week markings or unit-dose packaging can help patients track their medication intake and reduce the risk of errors.

2.6. Security

Pharmaceutical packaging plays a critical role in ensuring the security of the drug product and preventing tampering or counterfeiting. Features like tamper-evident seals, holograms, and serialization can help protect the supply chain and ensure that patients receive genuine and safe medications. Child-resistant packaging is also a crucial security feature for certain medications to prevent accidental ingestion by young children.

3. Types of Pharmaceutical Packaging:

Pharmaceutical packaging can be broadly categorized into primary, secondary, and tertiary packaging levels.

1. https://baobikienan.vn/tong-hop-nhung-cong-nghe-in-an-thung-carton-pho-bien-nhat-hien-nay/

2. https://baobikienan.vn/in-dap-noi-la-gi-va-nhung-dieu-can-biet-trong-in-an/

3. https://baobikienan.vn/the-art-of-allure-exploring-beautiful-cosmetic-packaging/

4. https://baobikienan.vn/giay-tam-carton-la-gi-dac-diem-cua-giay-tam-carton/

5. https://baobikienan.vn/top-10-dia-chi-mua-thung-carton-uy-tin-chat-luong-tai-tp-hcm/

3.1. Primary Packaging (Direct Contact with the Drug)

This is the packaging that comes into direct contact with the pharmaceutical product. The choice of primary packaging material is critical to ensure compatibility and prevent any interaction that could affect the drug’s stability or safety. Common types of primary packaging include:

- Bottles (Glass and Plastic): Used for liquid and solid dosage forms like tablets and capsules. Glass offers excellent barrier properties but is fragile, while plastic is lighter and less prone to breakage but may have lower barrier properties depending on the type of plastic.

- Blister Packs: Consist of individual cavities formed in a plastic film, each containing a single dose of medication, sealed with a lidding material. Blister packs offer excellent protection against moisture and oxygen and enhance patient compliance.

- Vials and Ampoules: Small glass or plastic containers used for injectable medications. Vials are typically sealed with a rubber stopper and a metal crimp, allowing for multiple withdrawals, while ampoules are sealed glass containers designed for single-use administration.

- Sachets and Pouches: Flexible packaging made from materials like foil laminates, used for powders, granules, and some liquid formulations. They offer good barrier properties and are convenient for single-dose applications.

- Tubes: Used for creams, ointments, and gels, typically made from plastic or metal. They provide good protection and allow for controlled dispensing.

3.2. Secondary Packaging (Outer Layer)

Secondary packaging provides an additional layer of protection to the primary container and serves as a platform for displaying product information and branding. Common examples include:

- Cartons: Typically made from cardboard, cartons hold the primary packaging and provide space for detailed labeling, including dosage instructions, warnings, and manufacturer information.

- Boxes: Similar to cartons but often larger and made from more robust materials, used for containing multiple units of primary packaging or larger pharmaceutical products.

- Trays: Used to group multiple primary or secondary packages together for easier handling and transportation.

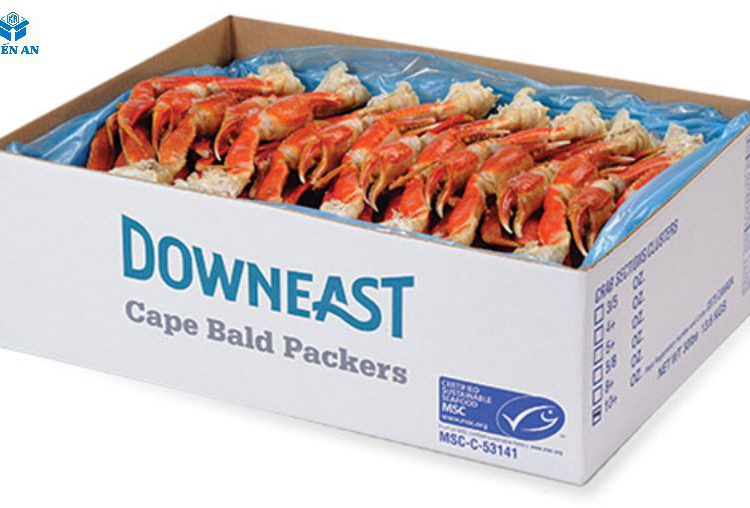

3.3. Tertiary Packaging (Bulk Transportation)

Tertiary packaging is used for the bulk transportation and storage of pharmaceutical products. Its primary purpose is to protect the products during shipping and handling. Examples include:

- Pallets: Flat structures used to support and transport multiple cases or cartons of pharmaceutical products.

- Shipping Containers: Large, standardized containers used for transporting bulk quantities of pharmaceuticals over long distances.

4. Key Considerations in Pharmaceutical Packaging Design:

Designing effective pharmaceutical packaging involves careful consideration of several critical factors.

4.1. Material Selection

The choice of packaging material is paramount and depends on the specific drug product, its dosage form, and its sensitivity to environmental factors. Materials must be non-reactive, non-toxic, and provide adequate barrier properties.

4.2. Child Resistance and Tamper Evidence

For certain medications that pose a risk to children, child-resistant packaging is mandatory. Tamper-evident features, such as seals and breakable closures, help to ensure the integrity of the product and alert consumers if the packaging has been compromised.

4.3. Patient-Friendly Design

Packaging should be designed to be easy for patients, especially the elderly or those with disabilities, to open and use. This includes considerations like easy-open closures, clear labeling, and ergonomic designs.

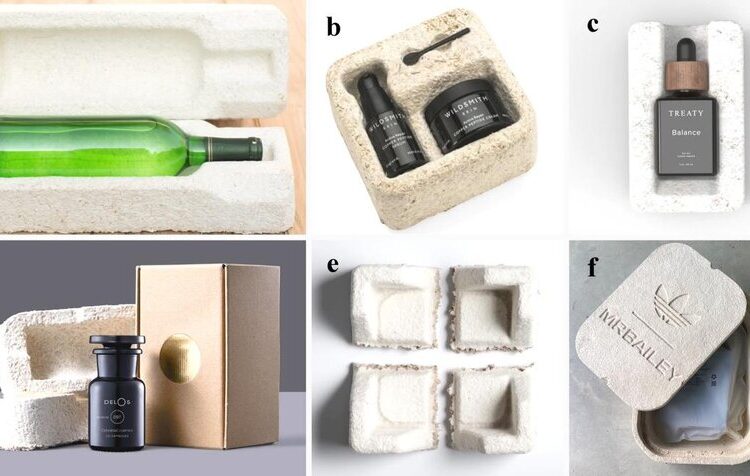

4.4. Sustainability

Increasingly, there is a focus on developing more sustainable pharmaceutical packaging options, including the use of recyclable materials, reducing packaging waste, and exploring biodegradable alternatives.

4.5. Cost-Effectiveness

While quality and safety are paramount, cost-effectiveness is also an important consideration in pharmaceutical packaging. Manufacturers strive to balance the need for robust and compliant packaging with economic realities.

4.6. Regulatory Compliance

Pharmaceutical packaging is subject to stringent regulations imposed by health authorities around the world. Compliance with these regulations is mandatory to ensure the safety and efficacy of medications.

5. Regulatory Landscape of Pharmaceutical Packaging:

The pharmaceutical industry is heavily regulated, and packaging is no exception. Regulatory bodies like the FDA in the United States and the EMA in Europe set strict standards for packaging materials, labeling, and security features. These regulations aim to protect patients and ensure the quality of pharmaceutical products. Labeling requirements are particularly detailed, specifying the information that must be included on the packaging and its format.

6. Emerging Trends and Innovations in Pharmaceutical Packaging:

The field of pharmaceutical packaging is constantly evolving, driven by technological advancements and changing patient needs.

6.1. Smart Packaging and Connected Devices

Smart packaging incorporates technologies like sensors, RFID tags, and near-field communication (NFC) to provide real-time information about the product’s condition, track its location, and even interact with patients to improve medication adherence.

1. https://baobikienan.vn/giay-thu-hoi/

2. https://baobikienan.vn/hop-dung-giay-la-gi/

3. https://baobikienan.vn/nen-su-dung-tui-dong-hang-hay-hop-carton-dong-goi-hang/

4. https://baobikienan.vn/phuong-phap-chong-tham-cho-thung-carton-co-the-lam-tai-nha/

5. https://baobikienan.vn/20-mau-nha-bia-carton-dep-tuyet-voi-cho-be-tai-sao-khong/

6.2. Sustainable Packaging Solutions

The industry is increasingly exploring and adopting sustainable packaging materials and designs to reduce environmental impact. This includes using recycled content, developing biodegradable materials, and optimizing packaging size to minimize waste.

6.3. Anti-Counterfeiting Technologies

Counterfeiting of pharmaceutical products is a serious global issue. Innovations in packaging, such as holograms, serialization, and track-and-trace systems, are being implemented to combat this problem and ensure the authenticity of medications.

6.4. Unit-Dose Packaging

Unit-dose packaging, where each dose of medication is individually packaged, is gaining popularity for its convenience, accuracy, and ability to improve patient compliance.

6.5. Packaging for Biologics and Temperature-Sensitive Drugs

The rise of biologic drugs and other temperature-sensitive medications has led to the development of specialized packaging solutions that can maintain specific temperature ranges during storage and transportation, ensuring the efficacy of these complex products.

7. Challenges in Pharmaceutical Packaging:

Despite the advancements, the pharmaceutical packaging industry faces several ongoing challenges.

7.1. Maintaining Sterility and Integrity

Ensuring the sterility and integrity of parenteral and other sterile products remains a significant challenge, requiring sophisticated packaging materials and manufacturing processes.

7.2. Ensuring Patient Safety and Compliance

Developing packaging that is both child-resistant and easy for elderly patients to open is a delicate balance. Improving patient compliance through innovative packaging designs is also a continuous goal.

7.3. Balancing Cost and Quality

Manufacturers face the challenge of providing high-quality, compliant packaging while managing costs in an increasingly competitive market.

7.4. Adapting to New Drug Formulations

The development of new drug formulations, such as biologics and personalized medicines, often requires innovative and specialized packaging solutions.

7.5. Meeting Evolving Regulatory Requirements

Pharmaceutical packaging regulations are constantly evolving, and manufacturers must stay abreast of these changes to ensure compliance.

8. Conclusion: The Indispensable Science and Art of Pharmaceutical Packaging

Pharmaceutical packaging is a critical and multifaceted field that combines scientific principles with innovative design. It plays a silent but indispensable role in safeguarding the quality, safety, and efficacy of medications, ultimately protecting patient health. From the fundamental functions of protection and preservation to the emerging trends of smart and sustainable packaging, the industry continues to evolve to meet the complex demands of the pharmaceutical landscape. The science and art of pharmaceutical packaging are essential components of the healthcare system, ensuring that patients receive the right medication, in the right condition, at the right time.